Cleaning and logo printing Contral Stage

Auto Assembly Line of LED Bulb

MOQ :1 set

Lead Time :90 Days

Seller Support : Trade Authenticity Guaranteed & Accepting

Payment : L/C,T/T

Departure Port : Xiamen

Product details

Supply Ability

- Supply Ability:5 piecesWarranty(Year):1 Year

Product Specifications

- Brand name:Wentian

Product Description

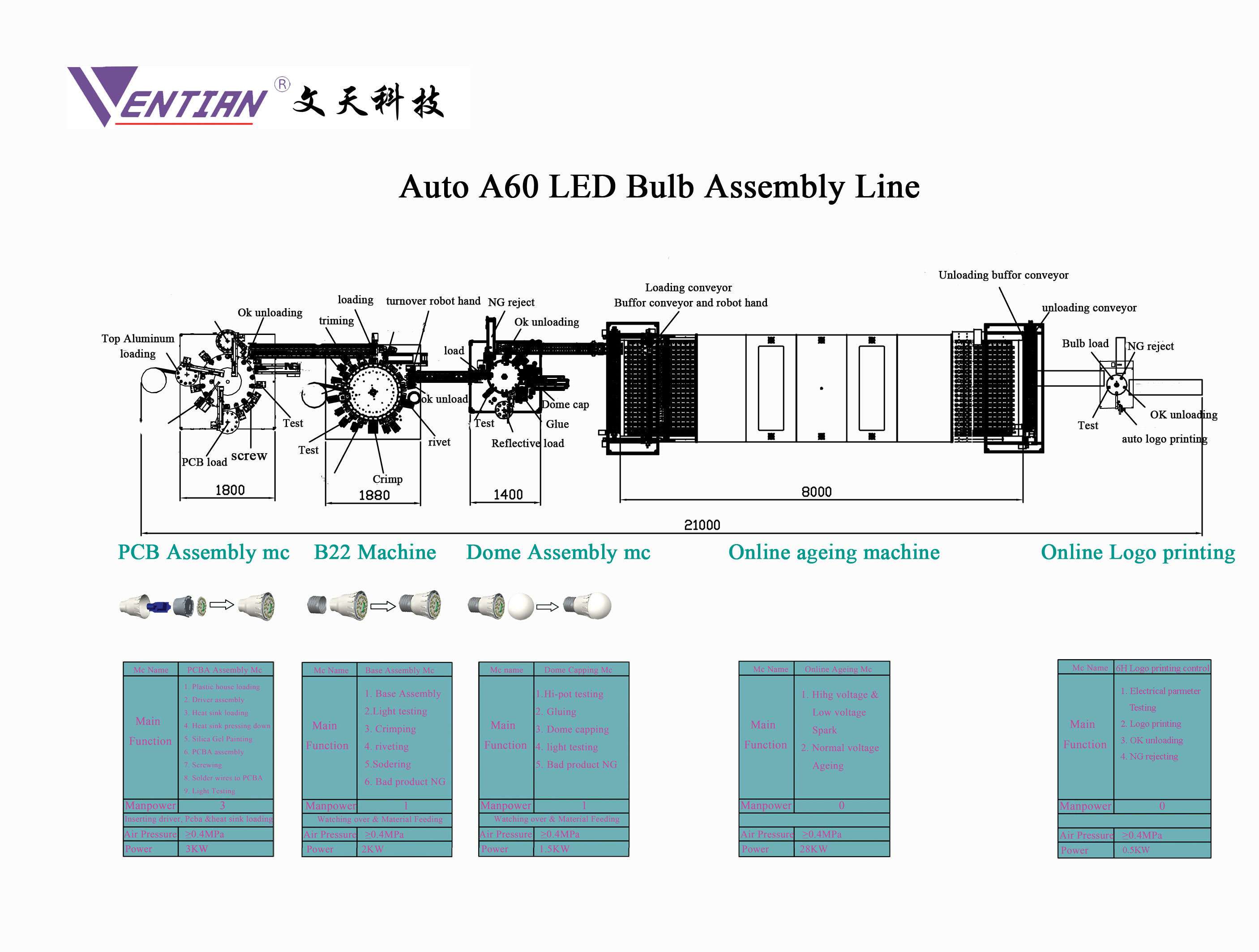

AutoLED Bulb Assembly Line Technical Proposal

Ⅰ.Auto Assembly Line Summary

1. This Auto assembly line isapplied to auto assembly, Ageing Testing and logo printing.

2. Suitable for Bulb with domedia.:φ45-75mm and Lamp Height: 80-130mm; B22 Cap.

3. Power consumption: 60KW; Airconsumption: over 6cbm; Air pressure around 0.6Mpa;

4. Machine length: 21M; arearequired: 25M*5M

5. Production line designed as1200pcs/Hour; 6workers

1) 2 workers for insertingthe driver into the housing and loading the Housing to the rotary chargingtray; and 2 workers for loading the PCB and dome to the rotary charging traysseparately;

2) 1 worker forfeeding the cap and top aluminum cap to the Vibration hoppers;

3) 1 worker forcollecting the finished goods

Ⅱ. Machine Process Descriptions

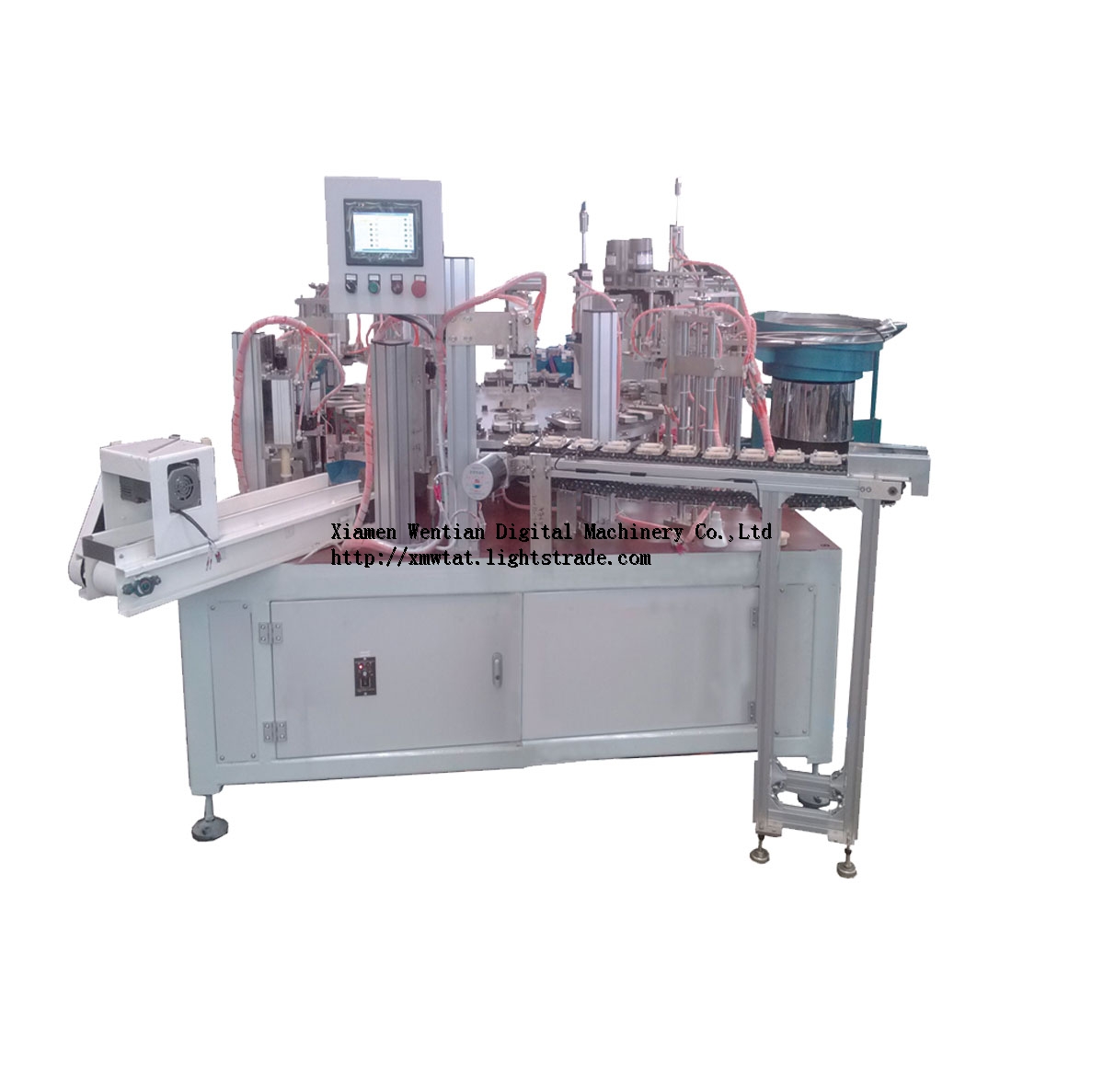

1. Driver and PCB assembly machine

1) Two workers to insert thedriver into the housing and load to rotary charging tray manually, then autoload by machine by robot hand;

2) Aluminum top assembly withthe housing: feeding through the Vibration hopper, and auto pressing down bycylinder;

3) Aluminum top assemblychecking;

4) Thermal Pasting;

5) One worker to load the PCBto the rotary charging tray, then auto load by machine by robot hand;

6) Screwing;

7) NG to NG conveyor, and goodproducts go to next machine.

2. B22 CapAssembly Machine

1) Base cap loading through the vibration hopper;

2)On/off testing;

3)Crimping;

4)Soldering,

5) NG to NG conveyor, and good products go to next machine.

3. Dome gluing and capping machine

1) CCDtesting for LED chips;

2) Glueapplication;

3) Oneworker for dome loading;

4)Dome capping;

5) NGto NG conveyor, and good product unloading to the output conveyor.

4. Online ageing machine

1) LED bulb ageing with B22 capholders;

2) 1250pcs/H, ageing time: 1hour;

3) Equipped4 sets of 25KVA voltage regulators, with 4 voltages:normal voltage ageing, high voltage ageing, normalvoltage spark, high voltage spark;

4) Indexing running controlledby stepper motor, auto loading& unloading.

5) With Mitsubishi PLC, andtouch panel operation interface;

Unloading from the previousmachine, transfer and load the bulbs to the next machine.

7. Cleaning and logo printing attachment and 2 laser printers

Cleaning the bulb by the alcohol firstly, then control the two laserprinters to print the logo; one worker is needed.

Ⅲ. Main parts Brand:

Mitsubishi PLC

ADVANTECH Industrial Computer

Air cylinder adopts SMC or Airtac brand.

Stand above the work table adopt the aluminum extrudedsections or steel sheet

You May Like

- Exhibitor

- Gold Supplier

- Trade Assurance

Business Type : Manufacturer,Service,Exporter

Company Location: FU JIAN

Year Established: 18YRS